Device Protection Beyond Ruggedization

Estimated reading time: 5 minutes

Table of contents

Presented at the SID 2018 Exhibitors’ Forum on March 22, 2018

Video of Presentation Here

Smartphones, tablets, point of sale devices, medical equipment, and other handheld devices are tools we use in our everyday lives. How many of you do not have a smartphone or tablet? Do the above image on the left look familiar to you? These devices have become part of our everyday lives, even becoming an addiction to many.

Why protect your touch screen displays?

Displays and touch panels are critical components in the functionality of a wide range of handheld devices: Medical devices, point-of-sale terminals, smartphones, tablets and more.

The display and touch panel is one of the first considerations design engineers make during the concept and development phase of a new product. In part, because they are one of the most costly components within the bill of materials. However, in many handheld devices, they are often left unprotected or protected by bulky plastics bezels and enclosures (a.k.a. ruggedization).

Displays and touch panels are subject to two conditions which cause them to fail:

- Scratches, from daily wear-and-tear or use of a stylus, where dust particles can become embedded on the tip and scratch the device. These scratches can cause a crack to propagate, which can eventually render the device completely useless.

- Drops onto hard or sharp surfaces, which typically cause instantaneous fractures.

Chemically strengthened glass

Chemically strengthened glass cover lenses or screen protectors are a great solution to this problem because they provide:

- Protection from scratches, which weaken the display/touch panel glass

- Protection from impact damage from falls or drops

- Maintenance of appearance and functionality

- Easy, low-cost replacement vs. replacing the display or touch panel

- In the case of screen protectors, a sacrificial layer that will break before the device, saving the device from expensive repair or replacement

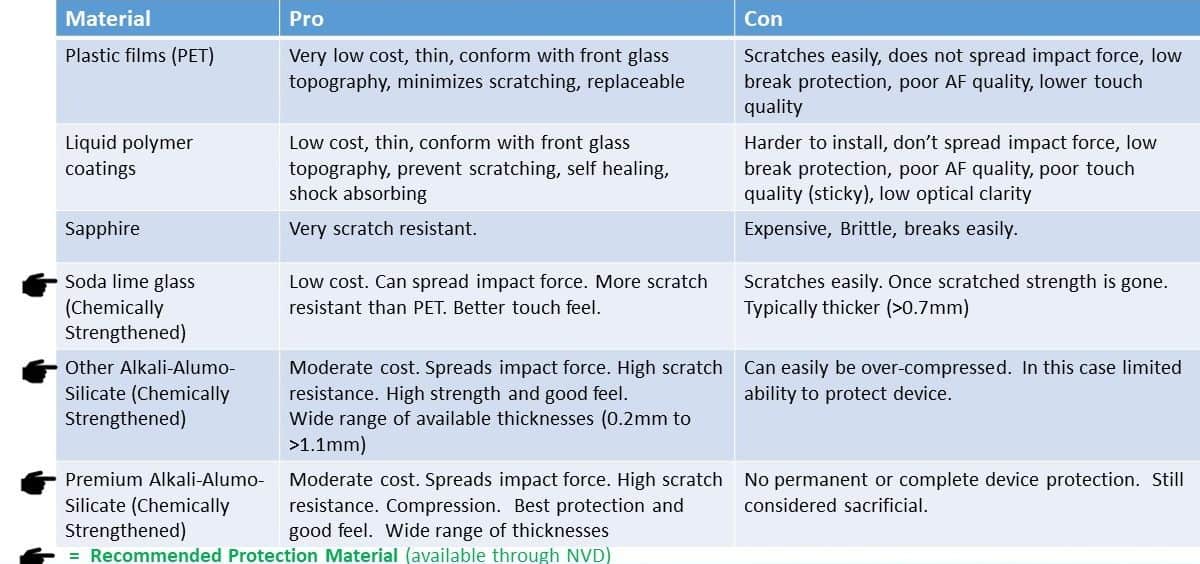

Cover lens and screen protector materials

There are a wide variety of cover lens and screen protector materials available to protect your device. But, what type of material should be used? Below is a summary, highlighting the pros and cons of each.

- Plastic films (PET)

- Pros: Low cost, thin, minimizes scratches.

- Cons: Scratches easily, low impact force absorption, low breakage protection, low touch quality.

- Liquid coatings

- Pros: Low cost, thin, conforms to front glass, self-healing, shock absorbing.

- Cons: Difficult installation, low impact force absorption, low breakage protection, poor AF and touch quality, sticky.

- Sapphire

- Pros: High scratch resistance.

- Cons: Expensive, brittle, breaks easily.

- Chemically strengthened soda-lime (float) glass

- Pros: Low cost, spreads impact force, better scratch resistance than PET, better touch feel.

- Cons: Scratches easily, once scratched the strength is gone, thick (typically >0.7mm for cover lenses)

- Mid-grade quality chemically-strengthened aluminosilicate glass

- Pros: Typically, better scratch and impact protection than above types, can be made very thin (from 0.2mm to >1.1mm).

- Cons: Neither the mother glass quality nor the ion-exchange process parameters are not strictly controlled, resulting in variable performance.

- Premium quality chemically-strengthened aluminosilicate glass

- Pros: Mother glass is optimally designed for specific applications, and the parameters for the ion-exchange process are strictly controlled, resulting in consistently high performance in scratch and impact protection

- Cons: More expensive than other materials.

The chemical strengthening process

Chemically strengthened glass gets its strength largely in part due to the ion exchange process. In this ion exchange process, larger potassium nitrate ions from a molten bath replace smaller sodium ions within the glass, creating a deep compression layer on the surface of the glass. This compression layer acts as “armor”, giving the glass incredible strength, scratch resistance, and breakage resistance from impacts due to drops.

But how is this proven? There have been formulas created by scientists that calculate the optimal strength of glass for different applications. Also, there are a number of tests used to evaluate the glass strength, such as a 3 and 4 Bar test (pictured right).

There are many other benefits to using chemically-strengthened aluminosilicate glass. It can be finished (processed) through very similar methods used with metals and plastics: Glass can be machined, holes drilled, bent into 3D shapes and more to fit your device.

Additionally, glass protectors can have:

- Anti-Fingerprint surface matching that of the original display or touch panel

- Variety of adhesives for applying the cover glass or screen protector to the device

- Specialized films and coatings: Privacy, anti-microbial, anti-glare, anti-reflection, blue light filtration, and more.

Whether you are a product designer or a consumer, take the next step in protecting your device with chemically-strengthened aluminosilicate glass. New Vision Display offers this solution for wholesale cover lenses and screen protectors. Contact us today to learn more!