The Science Behind Designing Displays for Healthcare

Estimated reading time: 11 minutes

Medical displays – done better.

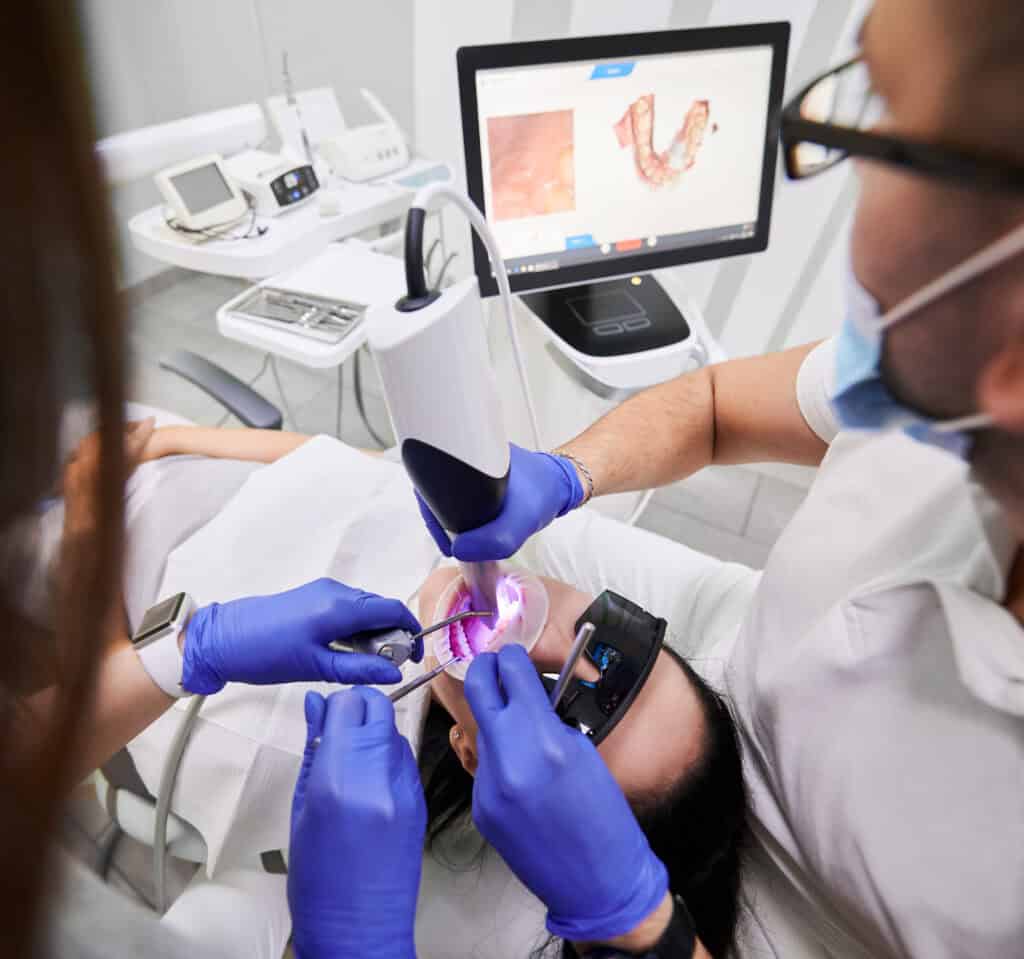

Imagine this: An EMT races to save a life, only to squint at a defibrillator screen in glaring sunlight. Or a radiologist leans closer to a monitor, struggling to discern critical details in an MRI scan.

In moments like these, a display is not just a screen. A good, high-quality medical display can make the difference between clarity and chaos, precision and guesswork, life and loss.

This is not hyperbole. Displays play an important role in healthcare, helping to transform raw data into life-saving insights. Thus, if you are designing or selecting displays for medical devices, be it for a hospital, a dental clinic, or a veterinary field kit, choosing the right display is critical.

In this article, we decode the science behind tailoring different displays to fit different medical contexts. We also explain how NVD, with over three decades of experience, is an expert in this science.

The Role of Displays in Medical Environments

Certainly, medical devices play a critical role in healthcare, with each device type subject to specific regulations based on its impact on patient safety. Display components must meet these standards to ensure reliability, safety, and effectiveness.

The classification of medical devices influences display design in the following ways:

Designing display components for medical devices requires a deep understanding of regulatory requirements, performance demands, and user needs. By leveraging expertise in regulatory compliance and display technology, NVD enables manufacturers to make informed decisions and deliver safe, effective, and compliant medical devices.

Customized Solutions Across Sectors

Every healthcare application comes with its unique set of requirements, and medical displays must adapt to these to ensure optimal results.

The Anatomy of a Great Healthcare Display

1) Built for the toughest environments

Because medical settings are as varied as they are demanding, their display components must be designed to perform seamlessly under challenging conditions. These include:

Some devices need to work in operating rooms or outdoor settings at freezing temperatures; others in blazing outdoor heat. Wide-temperature LCDs handle this range effortlessly, maintaining performance between -10°C and 70°C.

Displays often face dim hospital lighting or direct sunlight outdoors. Transflective LCDs provide dual functionality, reflecting ambient light during the day and using a backlight for low-light situations. OLED panels with adjustable brightness are a more thoughtful solution, offering contrast-rich visibility and customizable brightness.

Optical bonding can also help enhance sunlight visibility by eliminating the air gap between the display and the cover glass. This reduces additional reflections and glare, significantly improving contrast and readability in outdoor or high-ambient-light environments.

Moreover, ensuring that medical displays are outfitted with appropriate anti-reflective and anti-glare coatings is important, too – they help preserve the clarity and sharpness of the image being displayed, especially in high ambient light settings.

Display luminance is another key aspect to keep in mind when it comes to displays for medical applications. This is because medical displays need significantly higher luminance compared to typical computer monitors – they need to accurately visualize subtle details in medical images.

In fact, maintaining a stable luminance level over time is imperative for reliable diagnoses. Different applications (like radiology versus surgery) also have different luminance requirements, based on the type of images being displayed.

For medical imaging and diagnostic displays, particularly for applications like X-rays, gamma control is crucial. It governs how shades of gray are rendered between the deepest black and the brightest white, ensuring that all transitions are accurate and smooth.

Precise gamma functions maintain the true blacks, bright whites and consistent gray gradations required by medical imaging: when gamma is poorly calibrated, subtle details – like hairline fractures or soft tissue anomalies – can be obscured, potentially leading to misdiagnoses.

Emergency tools like defibrillators and monitors need ruggedized displays that can survive drops, constant movement, and vibrations.

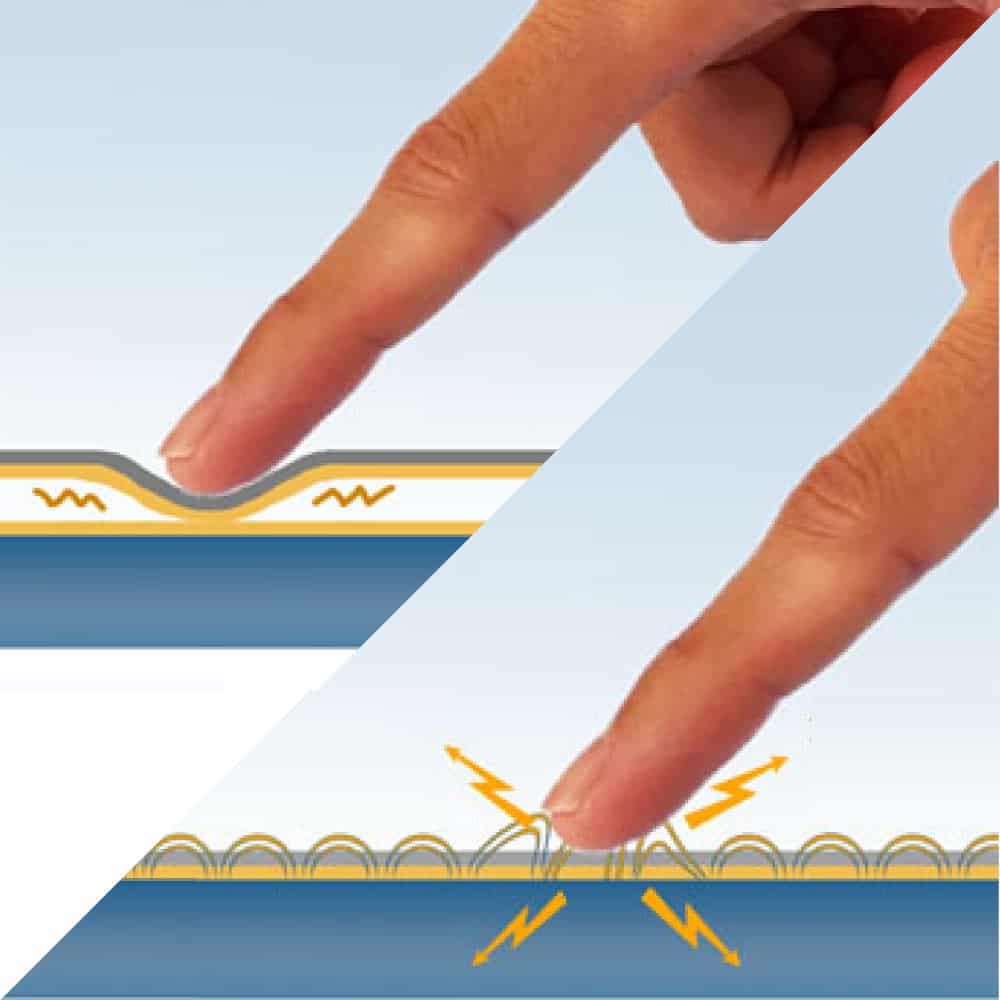

Optical bonding can help bolster vibration resistance by creating a solid, unified structure. However, its trade-off is the absence of an air cushion, which reduces the display’s impact resistance, making it more susceptible to cracking.

Here, reinforced housing for the display, using materials such as rubber or polycarbonate, can help in absorbing impact more effectively.

From sterilization chemicals to accidental spills, from blood to saltwater, from dust particles to bacteria: medical displays need protective measures like anti-microbial coatings, rugged seals, and IP-rated enclosures, to survive repeated cleanings and exposure to fluids.

Sensitive devices like pacemakers and ventilators must comply with strict Electromagnetic Interference (EMI) standards. EMI coatings must be applied to the device in order to prevent electromagnetic interference, which could affect device accuracy and tamper with critical readings.

Medical devices which need to be portable necessitate battery-efficient displays like ultra-low power Reflective LCDs (RLCDs) or power-saving OLEDs. These technologies extend operation time by conserving battery life, foregoing the need for frequent charging.

They also minimize energy usage – RLCDs by reflecting natural, ambient light, and OLEDs by scaling power usage, according to the content being displayed at the pixel level. Thus, making both OLEDs and RLCDs the more sustainable option environmentally.

Moreover, with less need for large, heavy batteries, OLEDs and RLCDs can also be designed to be slimmer and more lightweight – enhancing the device’s overall portability.

However, high power consumption does go hand in hand with medical applications which require displays to operate on high brightness, for better readability and faultless image quality. These applications include: pathology interpretation, endoscopic and laparoscopic procedures, and surgical visualization in operating rooms.

For medical applications, a touchscreen’s functionality is as critical as the display it serves. An excellent medical-grade touchscreen should offer:

- Precise Touch Input – precisely tuned to support faultless interaction during critical procedures.

- Exceptional touch sensitivity – for smooth operation even with gloves or styluses.

- Durability – to endure constant use and cleaning with harsh disinfectants.

- Hygiene & Safety – a seamless, easy-to-clean surface that’s resistant to fluid spills and bacteria buildup ensures safety in sterile environments.

- Enhanced Reliability – features like water resistance, EMI shielding, and glove compatibility improve performance in diverse healthcare settings.

- Superior Visual Clarity – anti-glare coatings improve visibility under bright operating lights.

2) Display appearance and features

Additionally, healthcare professionals need to interpret data quickly and accurately to make informed decisions. Thus, medical displays’ visual performance of is a top priority. This can be tailored in a number of ways:

Diagnostic imaging systems demand a vivid, true-to-life range of colors, while simpler monitoring tools can stick with monochrome for cost-efficiency. Moreover, it is important for all kinds of displays to retain stable luminance and color reproduction over their usage period, in order to maintain good picture quality, and withstand the degradation they undergo over time.

Displays need to match device ergonomics. Compact displays are preferred for handheld devices, while expansive panels are more suitable for imaging systems. Curved or wide-angle display designs are also gaining traction in surgical devices, to view imaging data from multiple vantage points.

Radiology displays require high-resolution panels (up to 4K or 8K) to catch minute details in CT scans or MRIs. In contrast, bedside monitors can use simpler resolutions to display basic metrics.

Displays must balance brightness with contrast for visibility which does not cause glare or eye fatigue. Features like anti-glare coatings and adaptive brightness sensors help maintain thisesolutions to display basic metrics.

3) Long-term reliability and compliance

Medical devices are not replaced every few years – they are investments that must endure for years to come. Hence, compliance and longevity are non-negotiable.

The Future of Medical Displays

Advancements in display technology are driving improvements in patient care:

Why Choose NVD? Because we know what matters.

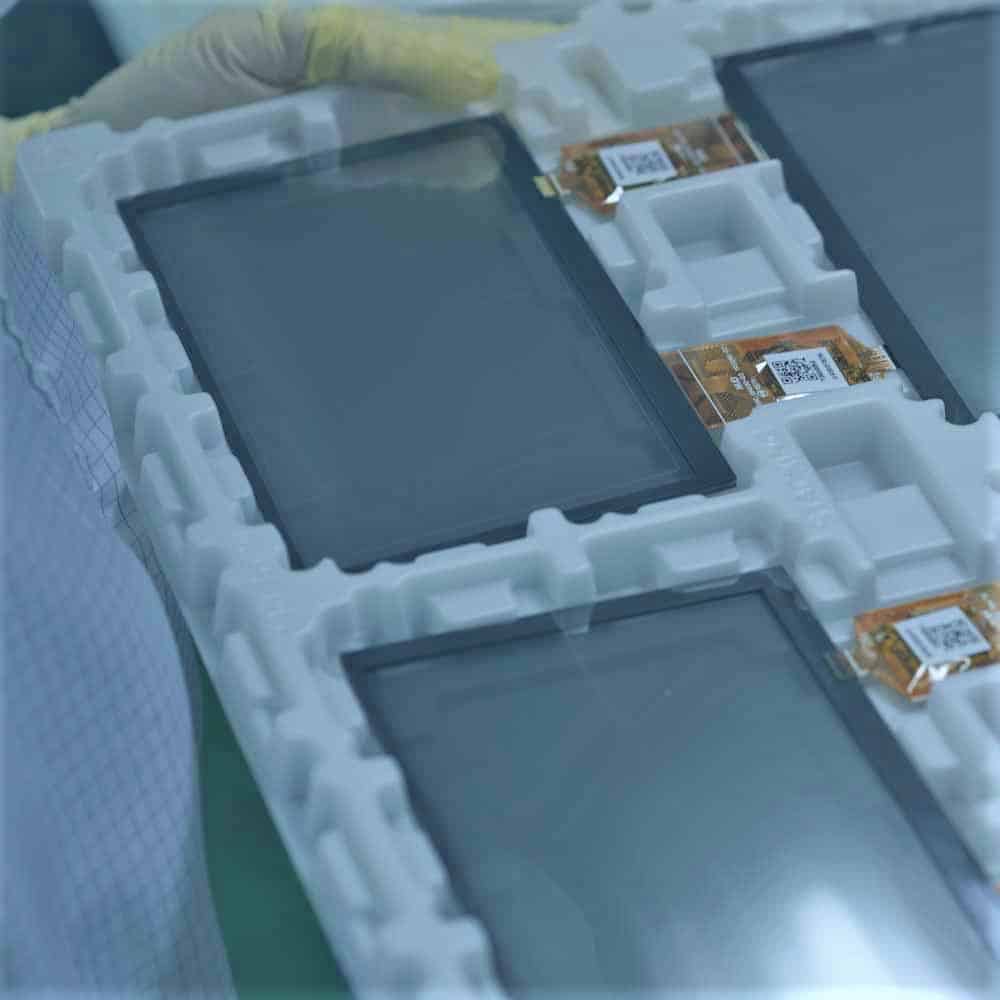

At New Vision Display (NVD), we specialize in designing and delivering high-performance displays tailored for specific healthcare applications. Whether you need compact, rugged displays for portable devices, or high-resolution panels for precision imaging, we can help.

Our core offerings include:

- Brilliant visibility: Sunlight-readable, anti-glare displays for any lighting condition.

- Durable designs: Shockproof, waterproof, and glove-friendly technology.

- Touchscreens and custom coatings: Touchscreens delivering precise functionality, with gloves and in fluid-heavy settings, paired with high-quality, custom-made screen protectors. Plus, a variety of coatings like anti-microbial, anti-fingerprint, and anti-glare.

- Energy efficiency: Optimized for portable and battery-operated devices.

- Long-term reliability: We build backward-compatible displays with guaranteed availability and clear, well-planned phase-out policies.

At NVD, we don’t just manufacture displays; we craft solutions that meet the highest standards. Let us help you find a tailored display solution for your medical devices.

Reach out to us at sales@newvisiondisplay.com or fill out our contact form to get started.