Standard vs custom display modules – what’s better for your project?

Estimated reading time: 4 minutes

When considering a display module for your project, sooner or later you’ll have to answer the question: “Should I design around a standard module or have one customized for my application?” The question is straightforward enough, but considerations that weigh into the answer can be as varied as the LCD module applications themselves.

Here are some tips, common misconceptions and answers to common questions that will help you with your decision.

Misconception #1: Custom LCD display modules have a higher unit cost

One common misconception is that custom display modules cost more than standard “off-the-shelf” modules.

While the above holds true for NRE cost, custom LCD module unit pricing is often equivalent to or lower than similar off-the-shelf product.

Here’s why: Standard display modules are often designed to maximize their implementation potential.

This can lead to:

- high pin counts that allow for variable interface protocols,

- high-output backlighting to maximize application potential,

- and generally conservative mechanical design practices (patented components, robust EMI solutions, metal bracketing, incorporated drive circuitry, and more).

For many applications, design-specific changes can reduce unit production cost through application-specific simplification, sometimes significantly so.

Misconception #2: Custom NRE costs are too restrictive

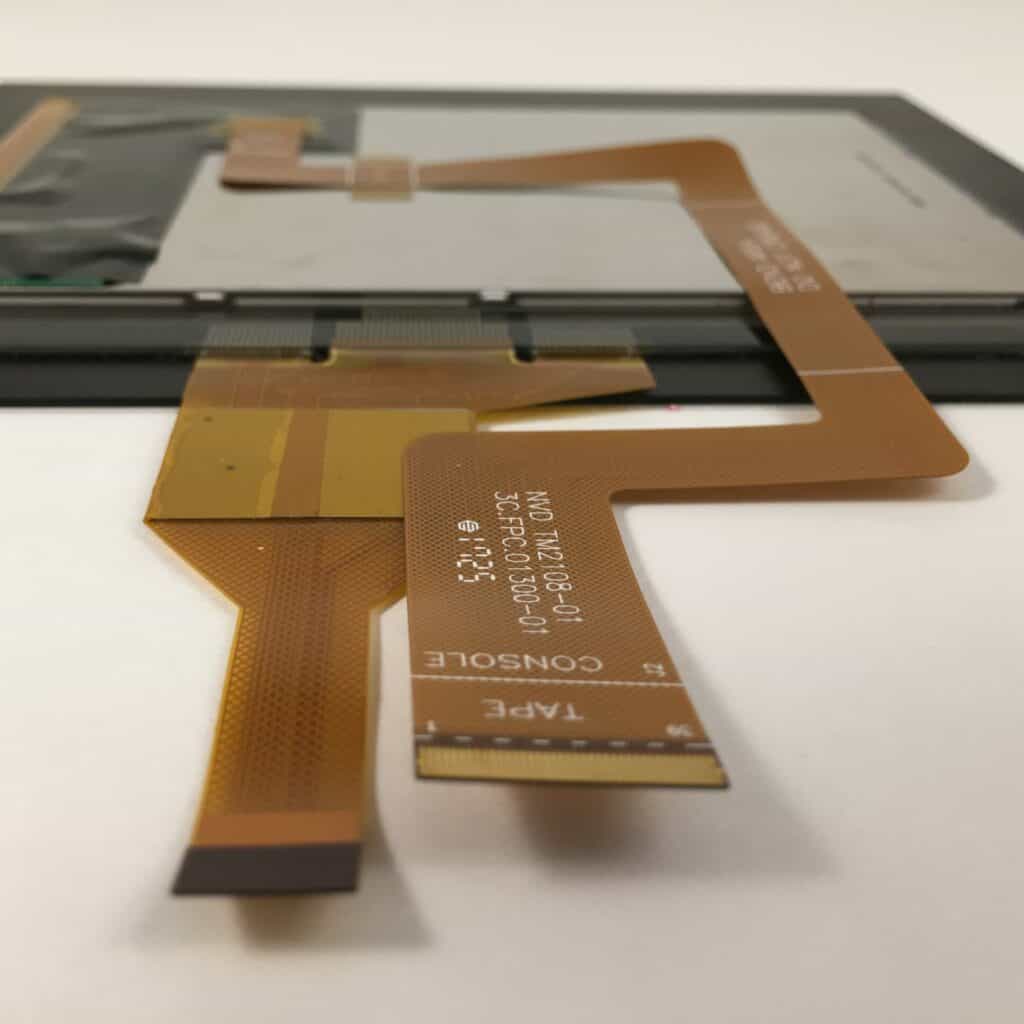

For most Passive Matrix LCD modules, New Vision Display can deliver a custom LCD (active area size and resolution), with custom back light, mechanical housing and electrical interface for a total NRE cost of less than $10k USD. Likewise, NVD can customize the back light, housing and mechanical interface of an Active Matrix LCD module for an NRE cost of less than $10k USD. In these cases, the design flexibility that customization allows for often justifies the modest NRE required.

Customizing the Active Matrix LCD itself (size/resolution), however, can be cost restrictive for most applications since the minimum NRE required for panel mask sets is around $100k USD. Unless project volumes are over 500k pieces per year (depending on size) or the scope of the business otherwise dictates a customer-owned TFT panel (e.g. guaranteed long-term panel availability), most designers find they are better off customizing around readily available TFT standards. In many applications the combination of a standard active matrix TFT cell with a custom designed module and electrical interface offers the most favorable overall cost solution.

Misconception #3: Designing custom modules extends lead time

Short lead time is another consideration that often makes off-the-shelf LCD modules attractive for designers. But, the lead time for a custom design can be shorter than you’d think.

LCD manufacturers like NVD can typically design custom housing for passive or active matrix LCDs – with integrated capacitive touch sensor and interface – within one to two weeks of the initial RFQ, and then provide sample custom LCD modules 4-5wks thereafter.

NVD also offers customers the option to use off-the-shelf modules as prototypes within their design, before the custom display is ready, so they can evaluate other design aspects and perform qualification work (e.g. testing software).

For many implementers, the design freedom and iterative optimization that customization offers is well worth the additional time required to sample custom LCD modules.

How NVD can help

New Vision Display manufactures standard and custom LCD modules with and without integrated capacitive touch panels and front cover lenses. NVD’s integrated display modules are available as off-the-shelf (“FastTrack”) products, as semi-custom display modules modified for specific applications, and as fully custom display modules designed from the ground up based on a unique set of customer requirements.

No matter the size and scope of your display application, NVD is ready to provide a solution with just the right amount of customization to meet your needs. Contact us below to learn more.