Single, Dual, and Multi-Touch PCAP User Interfaces

Estimated reading time: 5 minutes

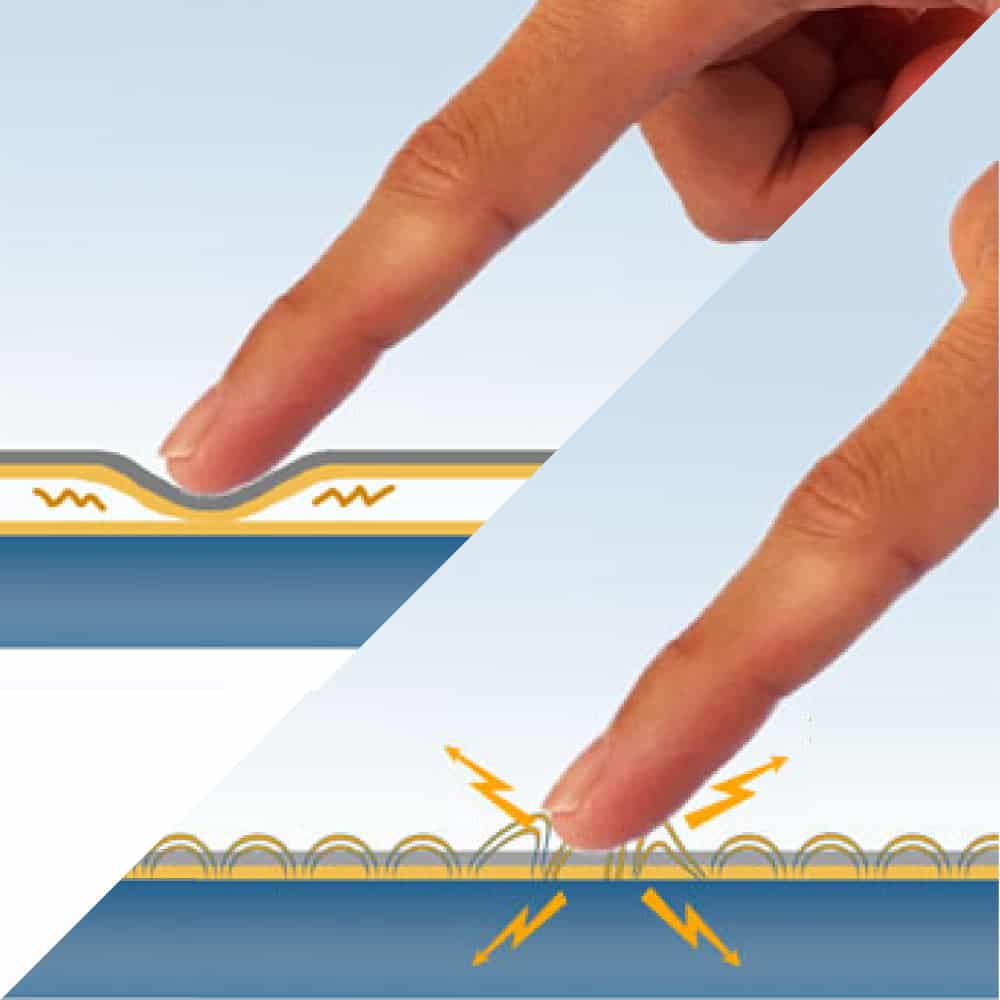

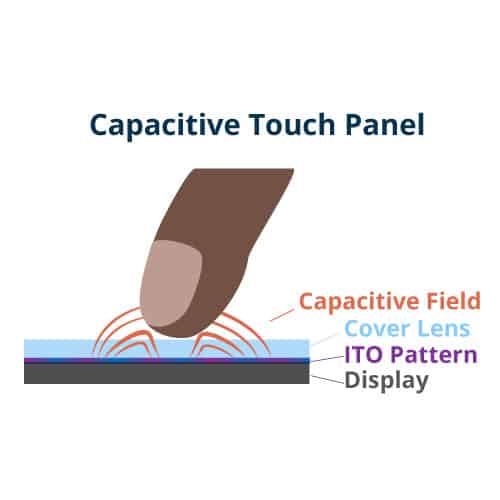

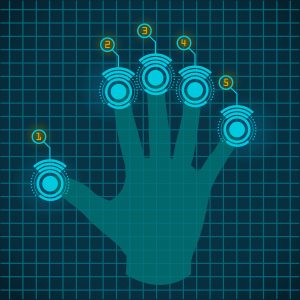

One of the biggest advantages projected capacitive touchscreen technology has over other touch technologies (especially resistive touch) is the capability to support the recognition of two or more distinct touches. This is why many OEMs who design capacitive touch sensors into their products, want to have this magical feature called “multi-touch”.

However, very few applications actually require a user interface that supports true multi-touch. For example, I have been using a smartphone for years and I can’t remember a single instance when I needed more than two fingers to operate any feature or game on that phone. Even the two-finger operation is limited to the zoom function. Therefore, it’s important to consider the scope of the product’s UI when designing a projected capacitive touch sensor and defining its specification. This way, OEMs can avoid designing-in an expensive touch panel, when one at a lower cost would be fully sufficient.

Here is an overview of the capacitive touch panel designs used in various user interfaces, and their performance related to the number of touches and supported gestures. The designs are listed according to their cost starting from lowest to highest.

1. Icon-based

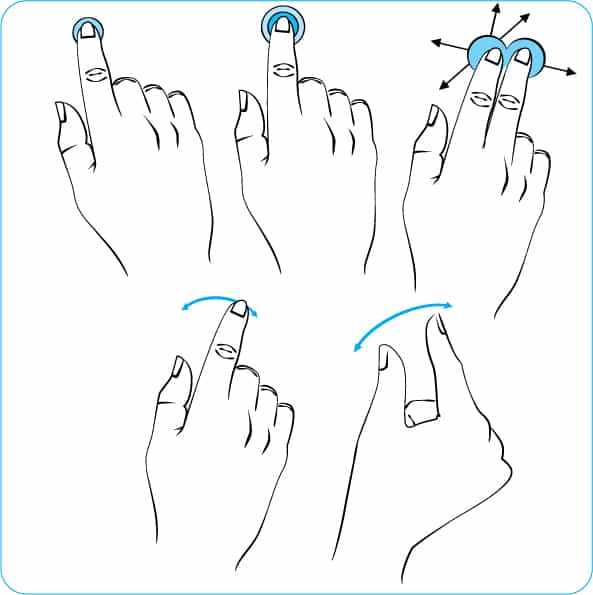

This type of PCAP touch UI utilizes predefined touch areas distributed over the screen. Within these touch areas are icons that display on the screen, often in varying menu screens. Gestures such as swiping or scrolling are not supported. The corresponding sensors only require a single layer of ITO with a predefined button layout and a simple button-type controller with limited input pins depending on the number of buttons.

2. Low-resolution, single-touch, gestures in one direction only

With this type of PCAP touch UI, single touches can be sensed anywhere on the screen, not just on predefined areas. It’s suitable for devices which typically don’t display pictures that require a zoom feature, but still need single touch gesture support for scrolling or swiping. This type of interface is commonly found in industrial and household applications, remote controls, and consumer medical devices. Here, the sensor can also be realized by a single layer of ITO, typically employing a triangle or backgammon pattern. Reliable gesture recognition is supported by this pattern only in one direction, i.e. either vertically or horizontally. It requires a simple capacitive touch controller with the number of inputs depending on the screen size. Typically, these types of sensors are limited to approximately 4” diagonal.

3. Medium-resolution with single-touch and single-and dual-touch gestures

This is a common PCAP touch user interface found on devices designed for very specific purposes, such as navigation devices, industrial, and professional medical devices. These typically feature pictures or maps that need to be zoomed but are not used for fancy games and applications. The sensor that supports such a UI typically exhibits a pattern of conductive rows and columns perpendicular to each other that are applied on a single substrate often referred to as a “caterpillar pattern”. This requires an elaborate layout where the rows and columns do not intersect on the visible part of the screen. The disadvantage of this pattern is the relatively low resolution it provides. It can be applied on sensors up to 5” diagonal.

4. High-resolution with multi-touch

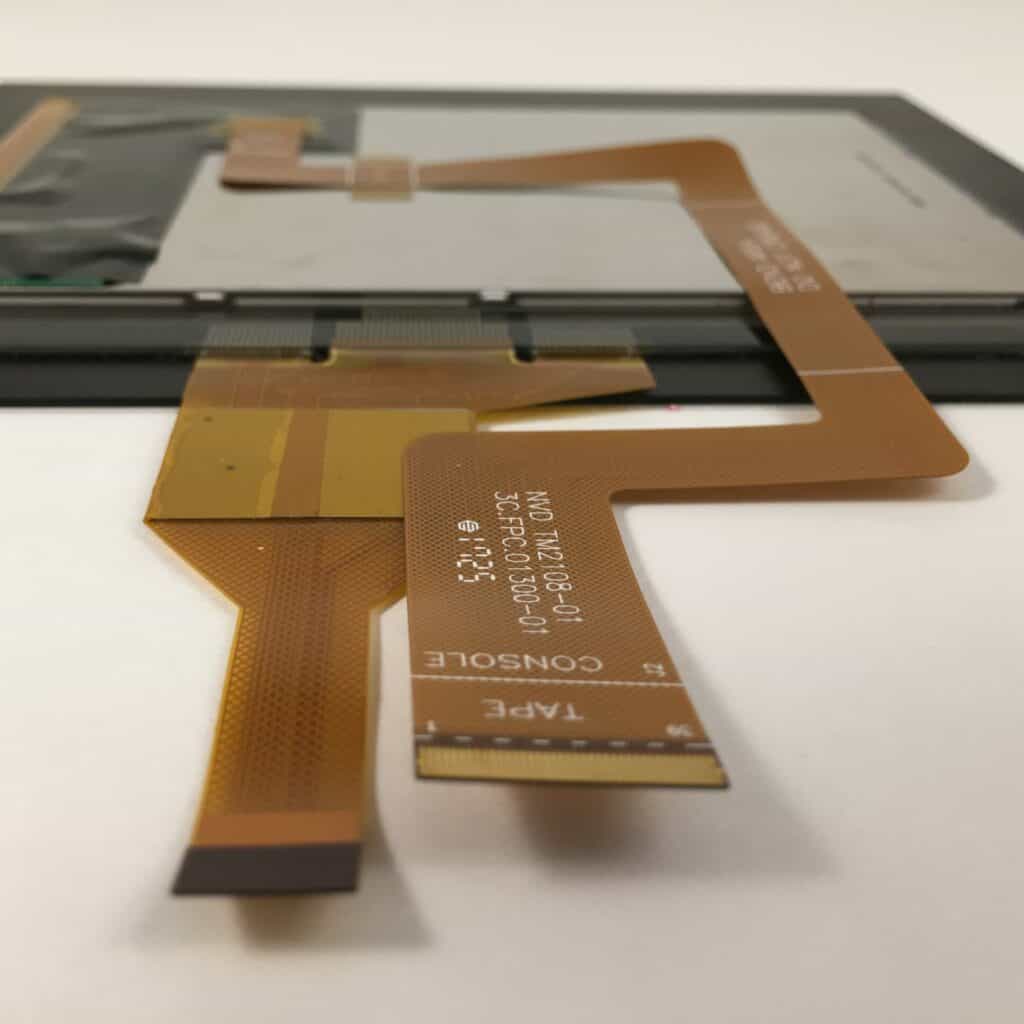

This is the most common PCAP touch user interface found on consumer devices such as mobile phones, tablets, laptops, and automotive applications. As mentioned above, the feature of “multi-touch” is not indispensable for everyday use, but sensors designed for higher resolution and larger screens practically provide this feature for free. Both high resolution and large size sensors require an ITO pattern on two different layers separated by a dielectric. This could be realized by laminating two substrates together (GG or FF), having the layers on opposite sides of the same substrate (DITO) or on the same side of a single substrate (SITO) where only the crossovers of the rows and columns of the sensing pattern are separated by an insulation layer. This 2-layer technology is the biggest cost factor that makes this sensor more expensive than the others. The only component specific to multi-touch is a controller that supports mutual capacitive sensing technology whereas a self-capacitive sensing touch controller would be sufficient for all the previously mentioned designs. However, such a controller does not contribute significantly to cost.

Looking for guidance? Give us a call. Our experienced sales team can recommend the right touch panel for your use case.