Touch Controller Tuning for Specific Applications

Estimated reading time: 6 minutes

Touch tuning requires technical expertise and in-depth understanding of the application.

Custom touch controller algorithms elevate touch and display products to their highest efficiency. That means optimized performance, dependable product life cycles, and greater differentiation in the marketplace.

So, how exactly does custom touch controller tuning work?

What is touch controller tuning?

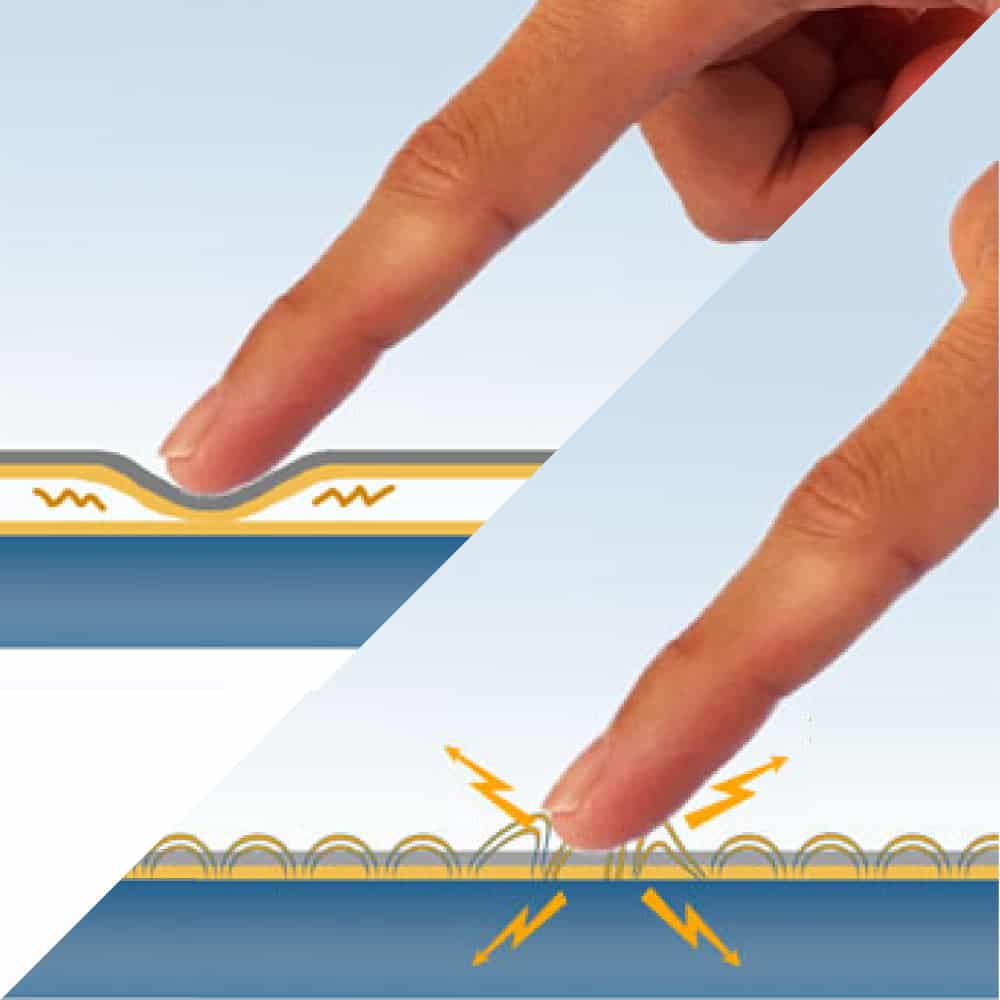

Touch tuning is the process in which a touch screen is optimized for maximum controller functionality. By adjusting certain sensitivity settings and tuning various touch objects, a touch display product can achieve peak performance under defined operational requirements.

The number of parameters potentially under consideration in the configuration process is enormous.

In highly complex and intense environments, there may be thousands of settings to tune for.

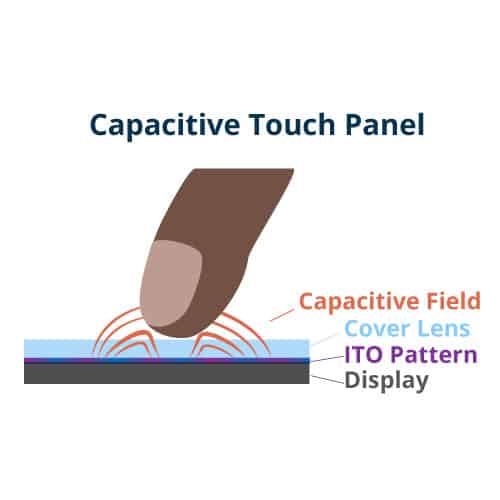

Touch controllers must be configured to meet application-specific requirements. The capacitive acquisition settings embedded in touch controllers enable “tuning” for performance as needed.

For instance, in marine settings, touch sensors must be tuned to not confuse highly conductive saltwater interference with a human touch. Similarly, if a product is designed for use with a stylus or heavy-duty glove (in addition to an exposed finger), a controller must be fine-tuned to optimize gain settings to allow for such versatility.

How does NVD excel in tuning for complex parameters?

Because of NVD’s long-standing history of tuning excellence based on customer needs and partnerships with touch controller providers, including Microchip and many others, NVD is the ideal partner for complex tuning projects.

Our partnerships with leading touch controller providers involve first-hand training and continued education of our in-house engineers.

NVD’s design and tuning capabilities allow customers to create designs with application-specific performance. And, NVD performs touch controller tuning internally — a task many other manufacturers must outsource to controller manufacturers.

Furthermore, NVD programs the touch controller chip in mass production, with the final tuning configuration as part of our 100% functional test procedure. This enables the customer to assemble the touch display into their system without any programming or tweaking of the touch controller at their end.

With NVD in charge of tuning, touch products arrive fully optimized and ready for optimal performance in customer applications.

Final environment tuning

New Vision Display configures custom controller algorithms and objects to ensure optimum functioning of integrated units.

Where NVD shows true excellence is in incredibly complex industries in which applications require highly customizable touch performance, such as:

A common challenge manufacturers and engineers face is balancing multiple conflicting requirements. Enabling optical, environmental, size and sensitivity settings to perform in complete harmony is no easy feat, and often leads to difficult compromises to achieve final product performance.

Automotive

Medical

Saltwater/Marine

Industrial

NVD works start-to-finish with the end application and environment in mind, deftly navigating touch screen display conflicts so that the product achieves its full potential. Plus, because NVD uses custom algorithms to provide next-level configuration, products can always be further refined and re-tuned, tailored to suit the final environment.

Tuning expertise makes all the difference between nixing a great idea or producing a remarkably inventive product. Settling for standard tuning is akin to settling for a standard product the market has seen before. When dealing with custom products, custom tuning is critical to ensuring market differentiation.

Testing and tuning for the future

When working with customers, NVD establishes true partnerships, serving as a strategic innovator throughout the entire design and development process.

Recognizing that a touch display product might originally appear feasible at the product sample stage but encounter unforeseen challenges at scale, NVD focuses on end-use.

NVD tests and tunes continually at every phase of the development process, so that inefficiencies or errors are weeded out early and the final product is fully capable of dependable operation in its final environment. Part of this level of foresight also entails making the right material choices from the start and working directly with customers to arrive at a reliable solution.

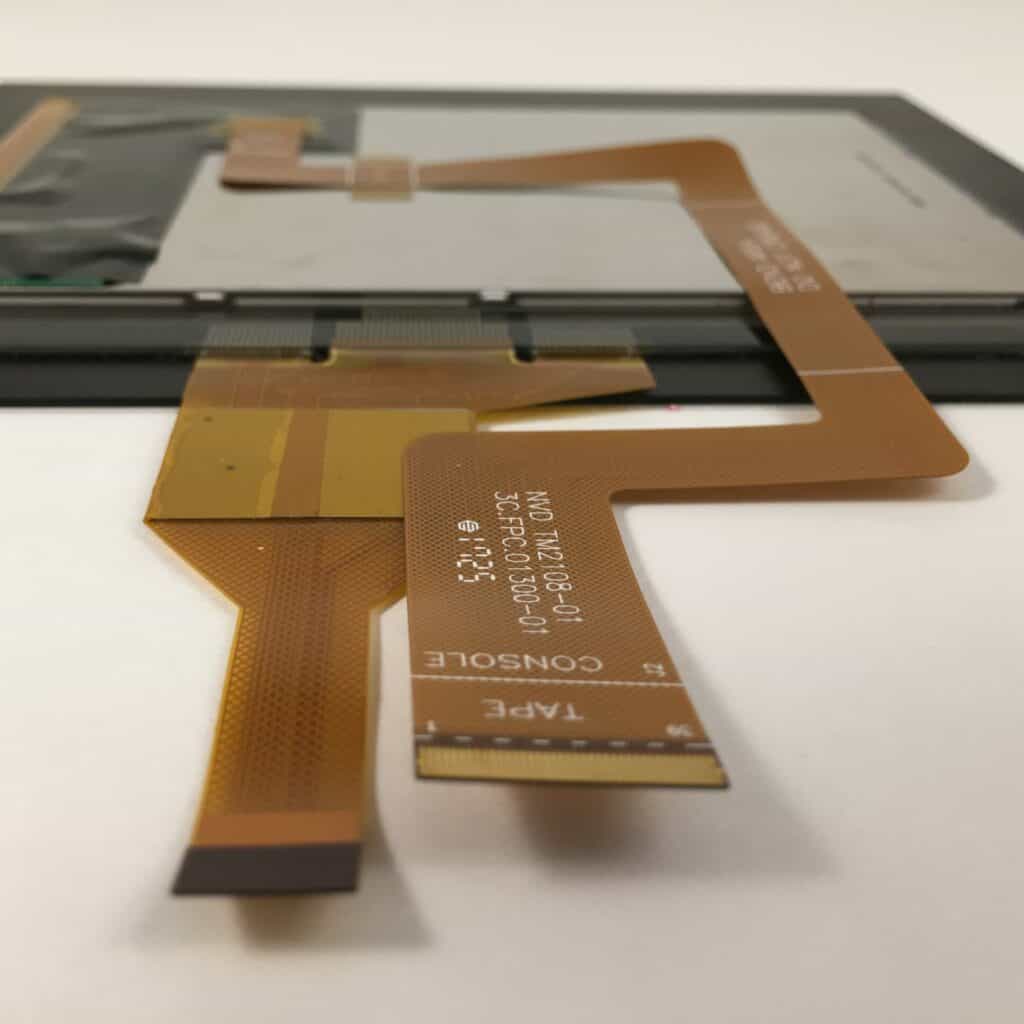

Reliable Liquid Crystal Display Modules (LCM) with integrated Projected Capacitive Touch (pCap) products require the proper materials and custom sensitivity tunings.

With more than 30 years of tuning expertise and global relationships with top original equipment manufacturers (OEMs), NVD is trusted to perform a multitude of critical tests like ElectroMagnetic Compatibility (EMC) and ElectroMagnetic Interference (EMI), among others.

With continuous testing and tuning solutions, NVD pushes the boundaries of touch and display product innovation. As a Tier 1 supplier in complex industries like automotive, the breadth and experience NVD brings to every customer interaction is unparalleled.